PVC HONEYCOMB FILLS / ABS HONEYCOMB FILLS / DRIFT ELIMINATORS / SIGMA FILLS AVAILABLE

Cooling Tower PVC Fills

While the reason for a cooling tower rotates around water, the genuine heart of any cooling tower is the fill. Fill, or wet deck or surface, is a medium utilized as a part of cooling towers to build the surface region of the tower. Expanded surface territory considers most extreme contact between the air and the water, which takes into consideration more prominent dissipation rates. The fill gives a tremendously extended air-water interface for warming of the air and vanishing to occur. The water is cooled as it slides through the fill by gravity while in immediate contact with air that disregards it. The cooled water is then gathered in a frosty water bowl beneath the fill from which it is pumped again through the procedure to assimilate more high temperature. The warmed and dampness laden air leaving the fill is released to the climate at a point remote enough from the air bays to keep its consistently stepped go into the cooling tower.

The principle of operation of cooling tower fill is to put as much water surface area in contact with as much air as possible, for the longest amount of time possible. Film fills allow the water to form thin flowing sheets to expose as much water surface area as possible to the interacting flow.

Cooling tower sheet fills or media, come in many different forms and “micro-structures,” each having unique characteristics to fit various applications. Film fills are selected for direct replacement, performance enhancement, and water condition compatibility. Each fill has performance characteristics that allow selections to be made for various heat loads, flow rates, water quality, and horse power combinations.

Cooling tower fills of size 600 x 300 ( 1 CFT ) and 600 x 150 ( 1/2 CFT ) made of corrugated virging quality PVC film duly vacuum formed and edge folded for extended service life. Available in blue and black colors for cooling tower of FRP induced draft counter flow type and cross flow type. The edge folded technology will reduce the attrition loss of the fills and save the process equipment from fouling . extend the service life of pvc fills for years

PVC Fills for Cooling Tower – We are one of the leading manufacturer & seller of PVC honey comb type corrugated PVC fills for cooling tower. Our fills are edge folded with 2. 35 mm thick virgin PVC film vacuum formed corrugated sheets pasted together to form the size of 600 x 300 x 150 mm having wetted surface area of 5. 85 sq. Mtr / CFT fill

Drift Eliminators

PERFECT offers Drift Eliminators, made out of rigid PVC, are designed to remove entrained particles from air steam efficiently, with minimum pressure drop, thereby reducing the fan power requirement when the air passes through the Drift Eliminator.

Cooling tower fills of size 600 x 300 x 150 mm ( 1 CFT ) and 600 x 150 x 150 mm ( 1/2 CFT ) made of corrugated virging quality PVC film duly vacuum formed and edge folded for extended service life. Available in blue and black colors for cooling tower of FRP induced draft counter flow type and cross flow type. The edge folded technology will reduce the attrition loss of the fills and save the process equipment from fouling . extend the service life of pvc fills for years.

Sigma Fills

We are also one of the leading manufacturer and supplier of sigma type fills suitable for crossflow make cooling towers . the dimension are as per customer requirement , based on tower make and model no.we undertake site installation work and also supply new cooling tower as well.

About Different Types of Cooling Tower Fills

What Is Cooling Tower Fills ?

Cooling Tower Fills are also named cooling tower filler, cooling tower filling, cooling tower fill packing, cooling tower fill media, cooling tower infill,cooling tower honeycomb fills etc.

Cooling tower fill is made of PVC or ABS plain plate by cooling tower fill making machine. They are hot pressed in the certain mould, and then be produced according to different design and be used in different cooling towers, especially in the industrial cooling tower.

No matter we how to name it, the main usage is a media located in the bottom or middle of the industrial cooling tower. Some of the towers will be filled with the filler, others will be half of the tower. Only large industrial tower needs to install 1 layer in the bottom.

Size and Shape of Cooling Tower Fills

Size and shape of cooling tower decide to use which kind of fill. Round cooling tower use the fill media with a square or rectangle shape. There is special shape of the ABS fill can be used in cooling tower too, for high temp applications.

About Cooling Tower Fill Material?

The raw materials of fills are very important. A good quality will assure you the cooling tower fill without any deformed in the process of using it. you can get pvc raw material green blue white round cooling tower filler. How to choose the good raw material?

We will help you to resolve the important point. We make the raw material PVC plate ourselves with 100% new polyvinyl chloride particle, the features are fast forming without deformed easily.

We also import the PVC overseas to produce the cooling tower fill according to every customer’s requests.

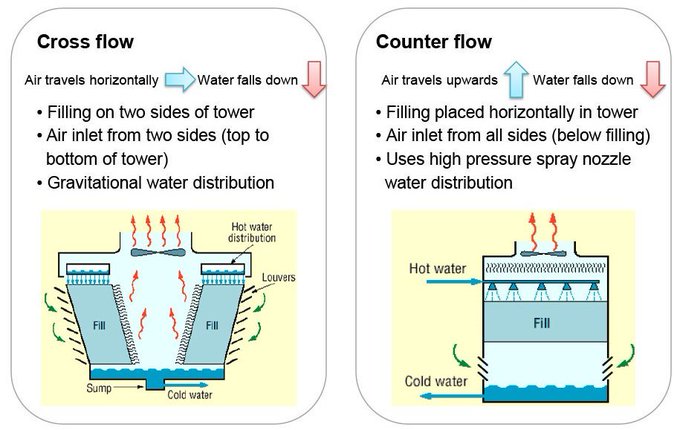

Cross flow fills VS Counter flow fills

Cross flow cooling tower fills

Cross flow cooling tower fill makes the water meet the air crossly, when cooling air enter the tower from two sides, the hot water come into the tower from the top.

The converging between hot water and cooling air is named cross flow.

The result is that the temperature of water get lower and flow away from the tower bottom, and the hot air is uprising in the tower top.

Counter flow cooling tower fill

Its working principle is all the cooling air enter the tower from bottom when the cooling tower fill located in the center is full of the tower

When the hot water come into cooling tower from the top, the cooling air will decrease the water temperature when all the water is scattered around the fill media surface.

After the temperature get down, the cooling water will flow out from the bottom, and the hot air lift in the top of tower.

Genuine PERFECT OEM parts are precision-engineered to provide you with a reliable product. While other suppliers may offer parts at an initial savings, you risk lowering performance — and losing FM ratings. PERFECT OEM parts provide the durability you can trust because we design and manufacture them exclusively for cooling towers. With plant operation relying on your cooling tower performance, it’s important to select the parts that are among the highest quality available — PERFECT OEM parts.