Our Location

No.153/1, 5th Main, 4th N Block,

Behind Suguna Hospital, SSI Area,

Rajajinagar, Bangalore – 560010,

Karnataka, India

📍 Get DirectionsDiscover durable, energy-efficient FRP cooling towers designed for industrial and HVAC applications, delivering superior performance and reliability.

Trusted by over 10,000 clients across diverse industries.

Installed Across 25+ Sectors

High Uptime Assurance

Built for Global Quality Compliance

Sustainable Cooling Technology

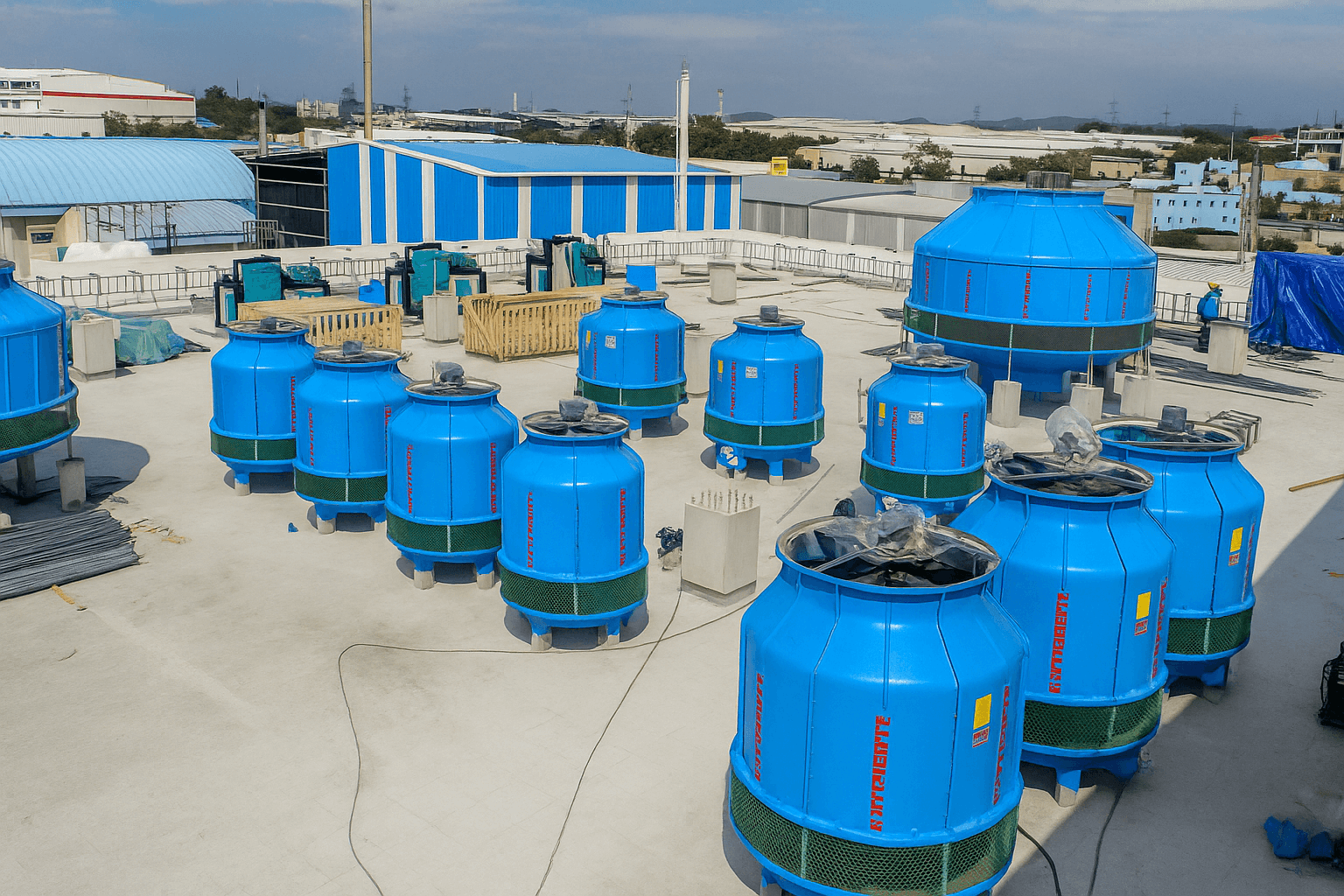

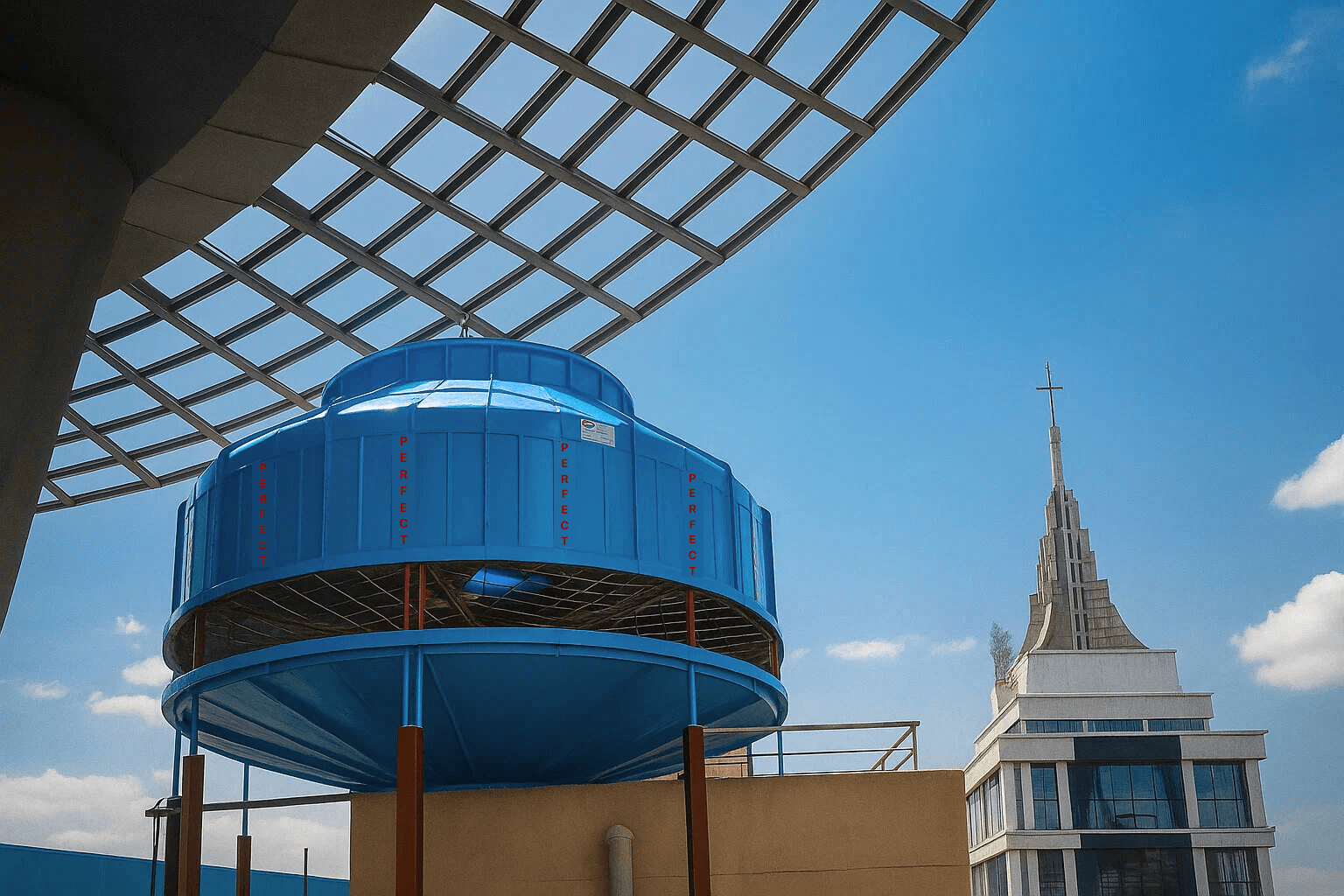

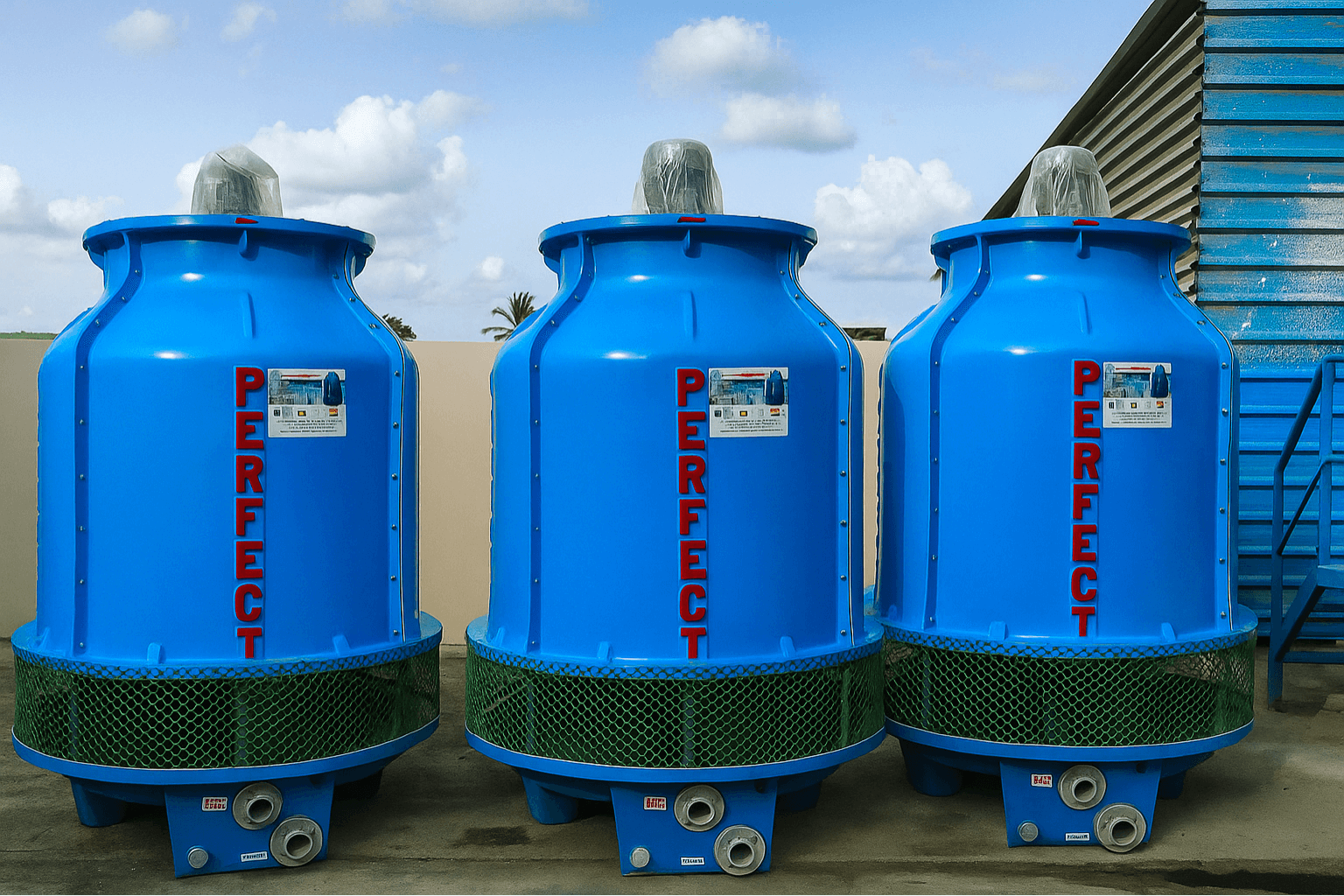

PERFECT Cooling Towers is India's leading manufacturer of FRP cooling towers, delivering innovative, durable, and energy-efficient solutions for industrial and HVAC applications. As the first cooling tower manufacturer in Karnataka and the No.1 cooling tower brand in the state, we proudly cool millions of litres of water every single day—powering thermal efficiency across diverse industries.

Cooling Experts

Call us anytime

+91 96111 34444

+91 97389 59931

Of cooling tower expertise

Experience optimum efficiency, our quality is unmatched

Crafted with decades of engineering know-how, our high-quality products use anti-microbial resin to reduce bacterial growth. We source raw materials from top suppliers to manufacture cooling towers that are efficient, maintainable, and cost-effective for the industry.

We offer high-efficient cooling towers at an affordable price with uncompromised quality, tailored to meet specific requirements. Our solutions ensure long-term reliability and performance, providing maximum value for your investment.

Perfect unequivocally guarantees the thermal performance of our equipment when installed in accordance with good practice. We provide unparalleled service and support for all types of cooling towers.

Discover the unique advantages of PERFECT Cooling Towers

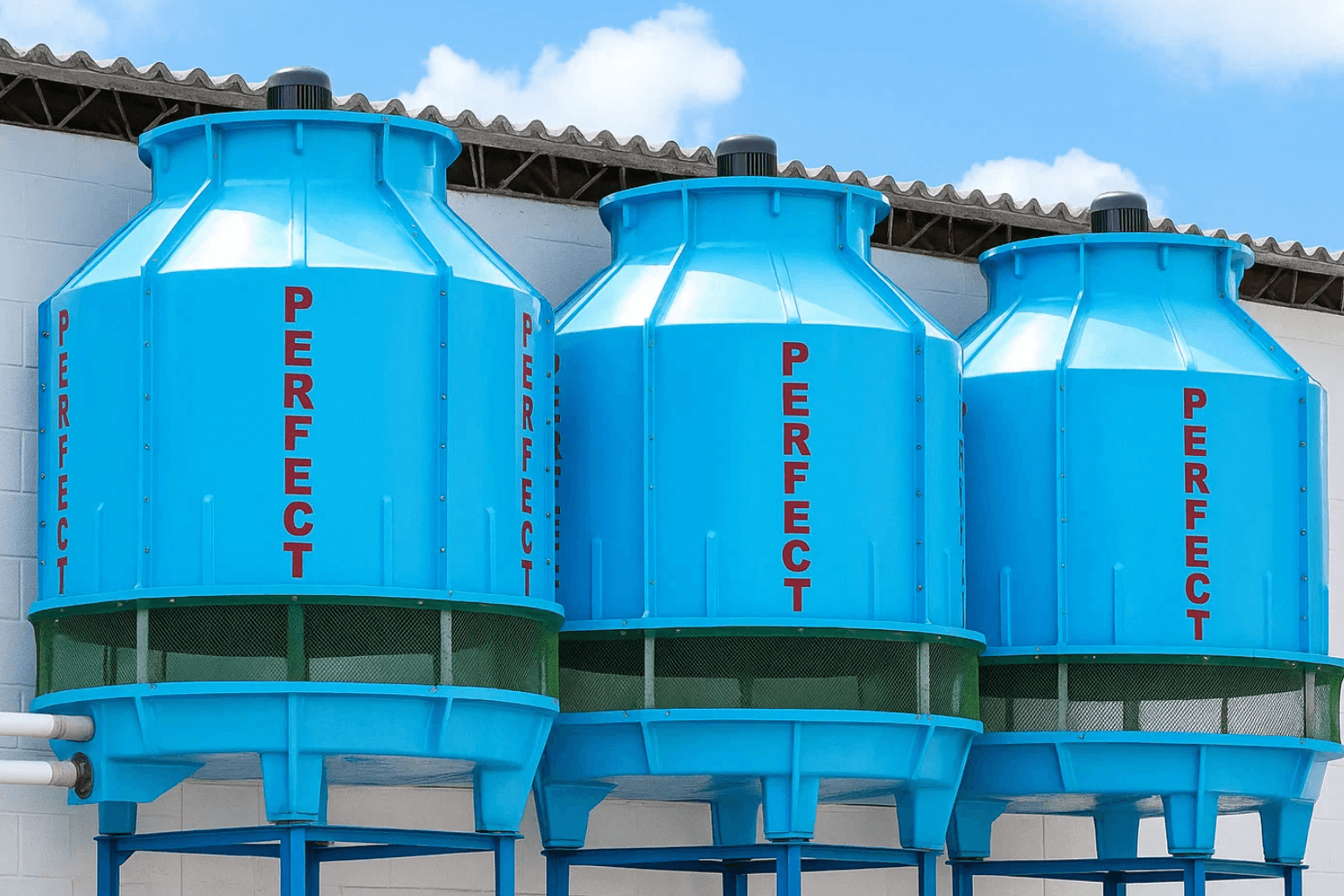

Our FRP cooling towers are engineered for demanding conditions—marine spray, high salinity, chemical exposure. With minimal maintenance requirements, they deliver stable and reliable performance for years to come.

Learn More About Durability

PERFECT Cooling Towers are trusted across industries for their adaptability and performance—delivering consistent cooling in diverse operating environments.

Explore All Applications

Unlike standard towers, PERFECT’s FRP cooling towers are engineered with built-in antimicrobial protection—designed to elevate operational hygiene, reduce health risks, and extend system lifespan.

Key Benefits:

Engineered spares for superior durability and compatibility with all cooling tower makes.

Fans, motors, fills, nozzles, and more for all cooling tower types.

Prompt dispatch to minimize downtime and keep systems running.

Expert guidance for spare selection and installation.

India's Leading Manufacturer of Durable, Corrosion-Proof Cooling Towers

A PERFECT Cooling Tower significantly enhances your system's efficiency by providing reliable heat transfer for any industrial process or HVAC equipment. Our energy-efficient cooling towers maintain optimal temperatures, leading to substantial energy conservation and reduced annual operating costs for your facility.

Say goodbye to frequent replacements. With PERFECT Cooling Towers, your maintenance costs will drastically decrease. Our highly durable FRP cooling towers are designed for optimal capacity, helping you avoid costly downtimes and significantly increasing your equipment's working lifespan.

Our modern FRP cooling towers come equipped with an advanced anti-microbial design. This innovative feature actively helps minimize the chances of harmful bacterial growth and contamination within your HVAC systems and general industrial cooling systems, ensuring a safer environment.

Tailored cooling towers for specific industrial and HVAC needs.

Reduces bacterial growth for safer operations.

Optimized designs for lower operational costs.

Suitable for HVAC, chemical, and manufacturing industries.

Seamless FRP shells reduce upkeep costs.

Lower carbon footprint with efficient cooling.

Submit your project details through our online form or reach out to get a tailored quote.

Our technical team will assess your requirements and recommend the best-suited cooling tower.

You’ll receive a detailed quote with pricing, delivery estimates, and technical specifications.

Get fast delivery of our plug-and-use cooling towers — minimal installation, ready to operate on arrival.

Join industries across India relying on PERFECT Cooling Towers for efficiency and reliability.

Request a QuoteReady Stock | OEM Quality | Fast Dispatch

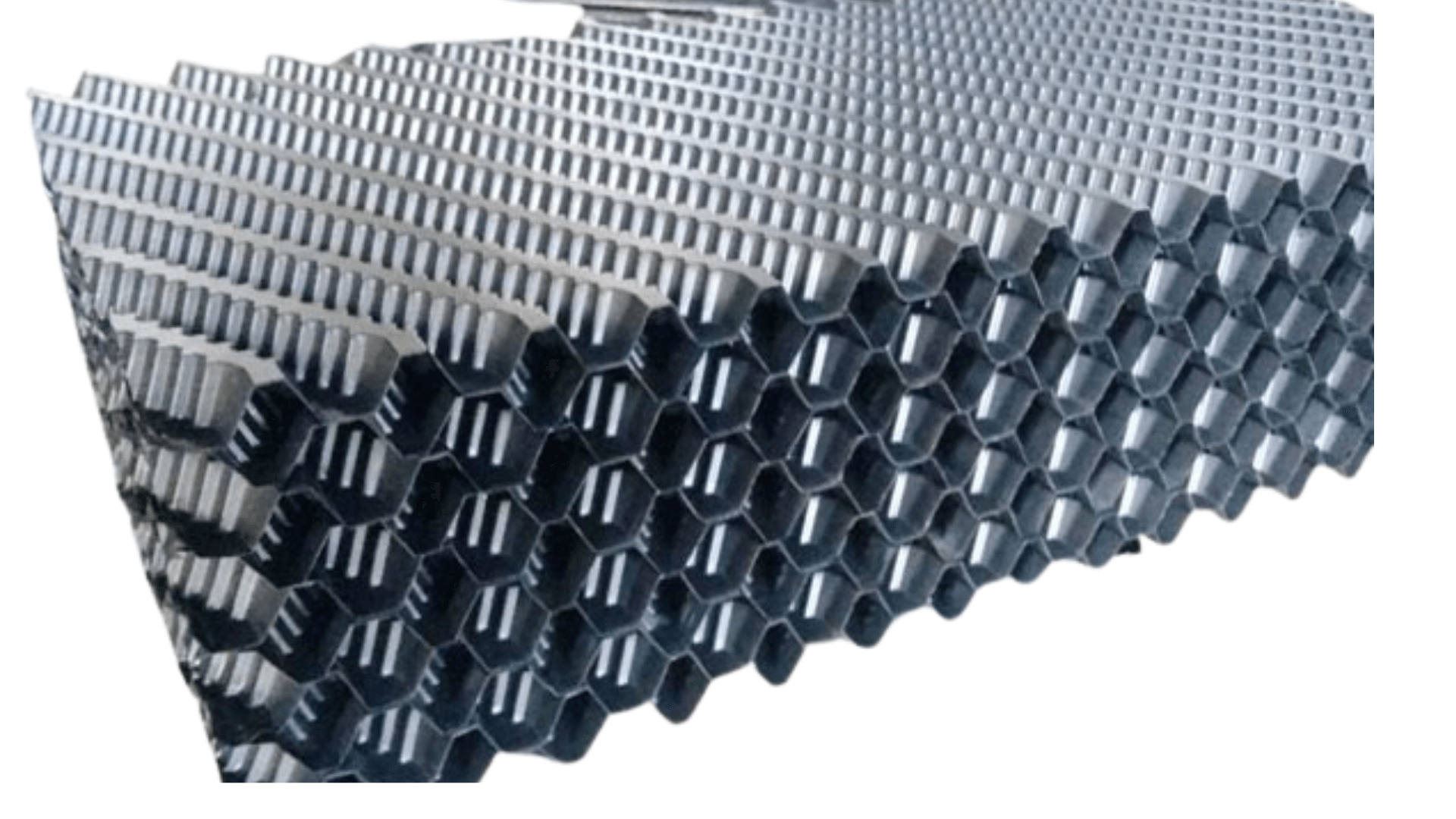

High-efficiency fills for enhanced air-water contact and thermal transfer.

Enquire Now

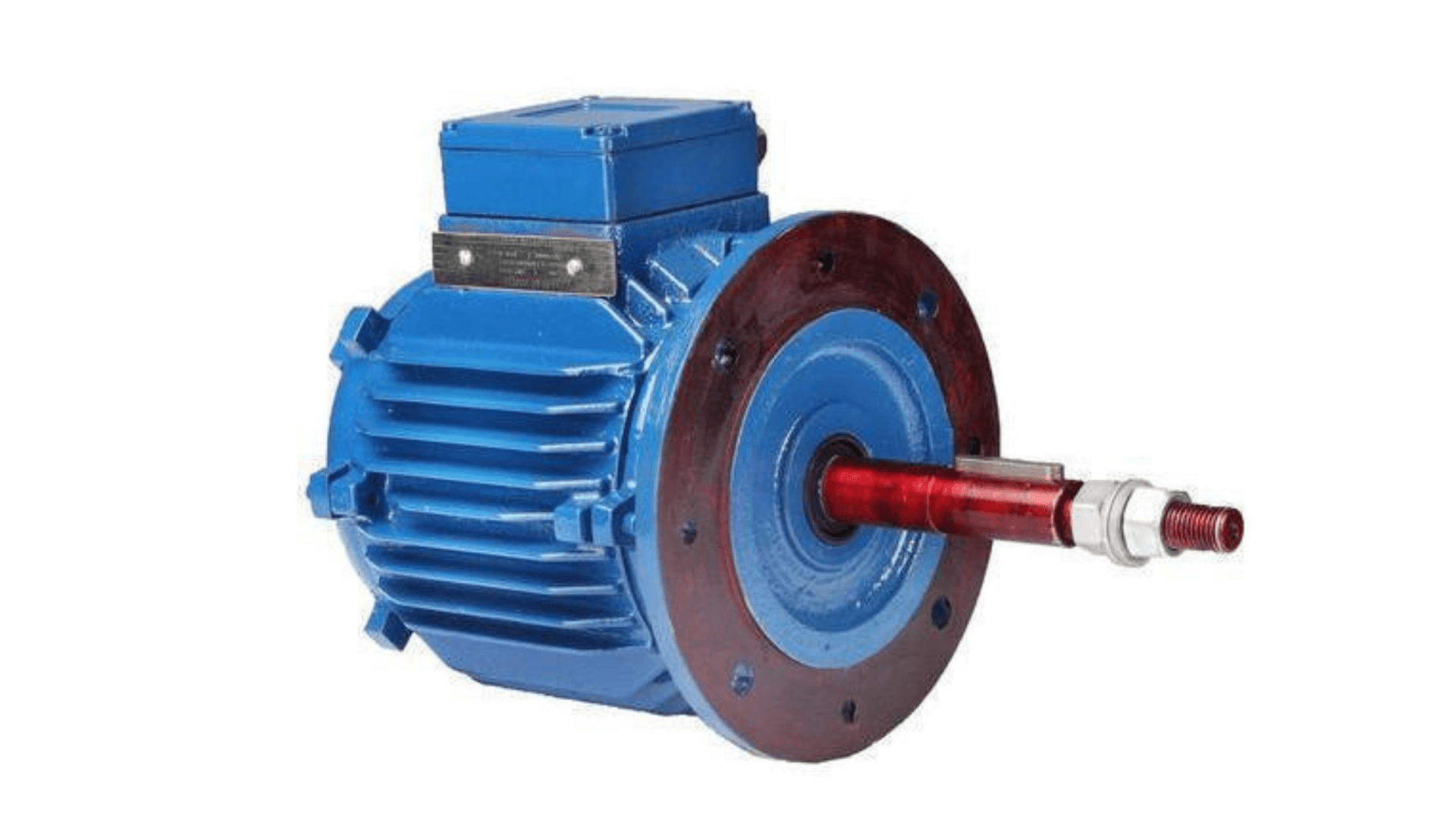

Weatherproof motors built for durability and efficient fan performance.

Enquire Now

Delivers uniform spray pattern for complete fill coverage and thermal efficiency.

Enquire NowTrusted by Thousands – Real Feedback on Our FRP Cooling Towers

We chose PERFECT Cooling Towers for their high-performance FRP cooling tower systems. Our operational costs dropped significantly due to their energy-efficient and low-maintenance design.

PERFECT’s anti-microbial FRP cooling towers enhanced the hygiene and efficiency of our HVAC system. They truly offer the best cooling tower solutions in India.

As a leading cooling tower manufacturer in India, PERFECT delivered a robust FRP cooling tower that transformed our industrial cooling setup. Highly recommended for quality and durability.

The prompt support and genuine cooling tower spare parts from PERFECT helped us reduce downtime. Their cooling tower maintenance service is the best we've experienced.

Delivering Excellence in Cooling Solutions Worldwide

Clients

Towers Built

Million Litres Cooled

Years of Experience

Delivering trusted cooling tower solutions with quality and reliability

Precision CAD Solutions: We use advanced design software and CAD techniques to create thermal and structural models for both counterflow and crossflow FRP towers.

Reliable Erection Support: Our experienced teams handle the complete on-site erection of cooling towers across industrial sectors, strictly following safety protocols and structural guidelines. We do not undertake commissioning, but ensure precise and safe installation.

Thorough Assessments: Our experts provide comprehensive tower inspections, structural reviews, and overhauls, ensuring maximum performance and safety.

Reliable Care: We handle scheduled maintenance, component replacements, and critical spare-part supply to keep cooling towers running smoothly.

Reliable, scalable, and tailored cooling tower systems for every industry

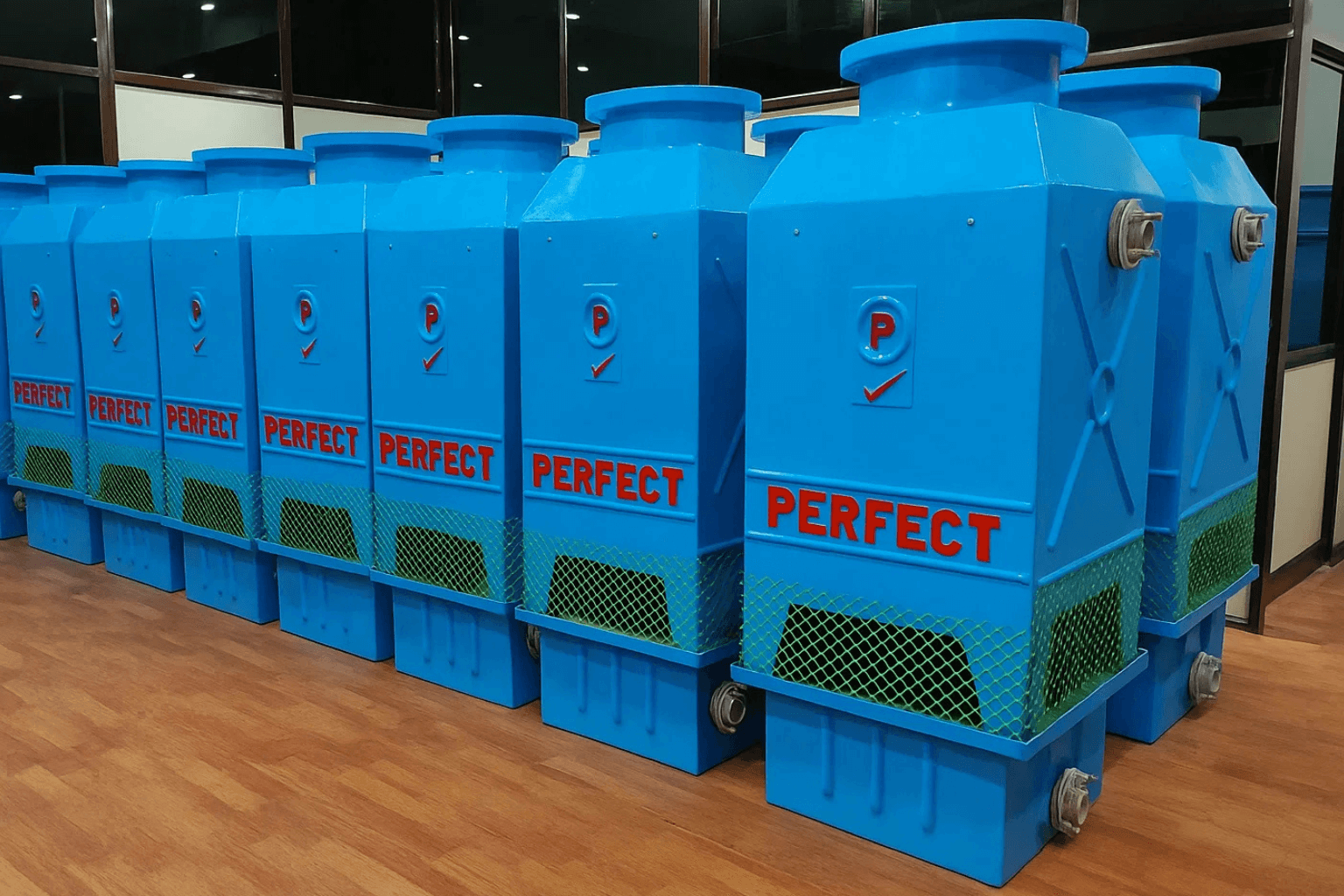

Compact and efficient cooling towers built with durable FRP shells and anti-corrosive components.

High-efficiency, low-noise cooling towers engineered for large-scale industrial cooling processes.

Wide range of OEM-compatible cooling tower spare parts for reliable performance and longevity.

Learn more about our cooling towers and services to make informed decisions for your industrial needs.

An industrial cooling tower is a heat rejection device used in HVAC systems, manufacturing plants, and power stations. It removes unwanted heat from process water using evaporative cooling, improving system efficiency and reliability.

FRP (Fiber Reinforced Plastic) cooling towers offer high resistance to corrosion, lower structural weight, excellent durability, and reduced maintenance costs. They are ideal for coastal, chemical, or high-humidity environments.

Our towers feature aerodynamic design, efficient fan systems, optimized fill media, and low-drift eliminators. These reduce fan load, improve heat exchange, and save up to 20% energy in continuous operation.

Basic maintenance includes regular water treatment, basin cleaning, nozzle inspection, fan belt checks, and ensuring proper airflow. FRP towers minimize rust and scale, reducing maintenance frequency and downtime.

Yes, we offer high-quality OEM-compatible spares like drift eliminators, fill media, motors, fans, and nozzles for multiple brands, ensuring performance and compatibility across tower types.

We assess your industry, water flow, heat load, temperature range, and local climate to recommend the best-fit cooling tower—counterflow along with ideal FRP specifications.

In counterflow towers, air moves upward while water falls vertically, allowing better heat transfer and compact design. Crossflow towers allow horizontal air entry and vertical water flow, making them easier to maintain but larger in footprint.

Approach is the difference between cold water temperature and wet bulb temperature. Lower approach indicates better cooling performance and energy efficiency in cooling tower operations.

Get in touch for your cooling tower needs

Reach out to us for expert cooling solutions and support.

No.153/1, 5th Main, 4th N Block,

Behind Suguna Hospital, SSI Area,

Rajajinagar, Bangalore – 560010,

Karnataka, India

📍 Get Directions+91–96111 34444, 97389 59931, 98450 65766

+91–80–4115 3796, 2314 4134, 2312 3615

Send us your inquiries, and our team will respond promptly.